WORK HOLDING

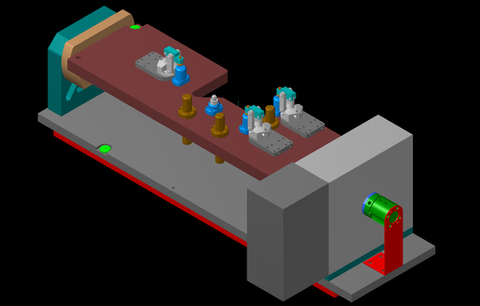

We have designed and built thousands of work holding solutions using pneumatics, hydraulics, and manual clamping for three and four axis machining, welding, assembly, electrical testing, leak testing, glue up, CMM, inspection, and quality assurance. We build fixtures that seamlessly integrate with existing machines to incorporate automatic clamping, part sensing, and sequencing.

Whether the part is a paper thin injection molded component, a billet work piece, aluminum extrusion, weldment, or 300 pound casting we can develop a manufacturing solution.

Tailored to Your Needs

With over 25 years of experience in the industry, Dimension Tool and Machining has designed and built thousands of work holding projects. Throughout our rich history, we have honed our expertise and gained invaluable insights into the diverse needs of our clients.

At Dimension Tool and Machining, we believe that a successful work holding solution is the backbone of an efficient and repeatable production process. That's why our team of seasoned professionals is dedicated to providing you with designs that optimize productivity, accuracy, and safety. We take the time to listen to your unique requirements, study your operations, and develop tailor-made solutions that align with your project goals.

Throughout the years, we have established long-lasting partnerships with our clients by delivering reliable customer service. We prioritize open communication, and a collaborative approach, ensuring that your vision is realized at every step of the process.

Experience the difference that our expertise and dedication can make in optimizing your production processes.